With the vigorous development of the global mining and energy industry, the continued growth of demand for mining and energy has become a significant phenomenon, bringing unprecedented opportunities and challenges to the mining machinery and equipment industry. This increase in demand has not only promoted the expansion of the industries but also promoted technological innovation and product upgrading. To continuously explore overseas markets, expand sales channels, enhance brand awareness, and achieve sustained business growth, our company is scheduled to participate in the WAMPEX 2024 West Africa Mining and Power Expo to be held in Accra, Ghana from June 5 to 7, 2024, to showcase the latest mining machinery equipment technology and solutions. We sincerely invite you to visit booth C13, communicate face-to-face with our professional team, and discuss the development of Ghana's mining industry.

According to data from the Ghana Mining Department, Ghana's mining output value has grown steadily and mining investment has continued to increase. China is one of Ghana's largest suppliers of mining machinery and equipment, and cooperation between the two countries in the mining field is becoming increasingly close. At the same time, according to data from the General Administration of Customs of China, Ghana is also one of the important import markets for China's mining machinery and equipment. In recent years, bilateral trade cooperation has grown steadily, providing strong support for Ghana's mining development.

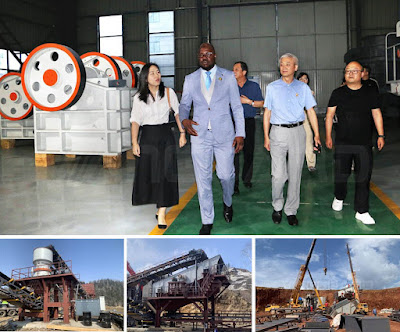

Vanguard Machinery has always attached great importance to the development of the African market, which is one of our strategic priorities. In the past few years, we have achieved a series of important results in the African market. Through close cooperation and an in-depth understanding of local customers, we provide customized solutions for various industries in Africa, covering mining, infrastructure construction and other fields.

Our products have been widely recognized and praised in the African market, and their stability, efficiency and reliability are highly trusted by customers. We have established long-term and stable cooperative relationships with African customers, jointly promoting the development of local economies and the progress of engineering construction.

As a professional mining equipment manufacturing company, Vanguard Machinery is committed to innovative design, improving product quality, improving product lines, and providing customers with all-round support and guarantees based on the full life cycle service concept. Our R&D team cooperates with top scientific research institutions at home and abroad to continuously explore new technologies and processes to meet the growing needs of customers. The production process is strictly implemented following the quality management system to ensure that every piece of equipment reaches the highest standards. In terms of sales and after-sales service, we always adhere to "customer first" and provide customers with professional consultation, solutions and around-the-clock service to ensure customer satisfaction and stable equipment operation.

The WAMPEX 2024 exhibition is about to open. This is an important platform to gather industry elites and discuss future development trends. Vanguard Machinery looks forward to communicating and cooperating with you at the exhibition site, working hand in hand with global partners, and jointly promoting the sustainable development of the mining and energy industries. Let's meet at WAMPEX 2024!