Vanguard Machinery is a professional manufacturer of mining machinery, including crushing and screening machinery and all other ancillary equipment.

2021-06-24

Jaw Crusher Testing Before Dispatching-Vanguard Machinery Tech

2021-06-16

Stone And Gravel Crushing Production Line-Quarry Crusher In Quinta, Ethiopia-Vanguard Machinery Tech

2021-05-30

Crawler Type Mobile Multi-Cylinder Hydraulic Cone Crusher-Vanguard Machinery Tech

2021-04-21

Why Choose Basalt As The Raw Material For Crushing? How To Configure The Complete Crushing Production Line?

The rock structure of basalt often has stomata, an almond-like structure, and a porphyritic structure. The common color is mostly black, dark brown, or dark green, and it is one of the common types of stone on land. Because of its excellent material, it is selected by many crushing production lines to produce high-quality sand and gravel aggregates. So why choose basalt? How to configure a complete sand and gravel production line?

Why choose basalt?

After the processing of the crusher, the porous basalt sand and gravel can be mixed into the concrete, which reduces the weight of the concrete and has the characteristics of firmness, sound insulation, and heat insulation. It is a good aggregate for lightweight concrete in high-rise buildings. In addition, because basalt stone has the advantages of wear resistance, low draft, poor electrical conductivity, strong compression resistance, low crushing value, strong corrosion-resistance, and asphalt adhesion, it is the best material for repairing roads, railways, and airport runways.

How to configure the basalt crushing production line?

Take the customer's crushing production line of Vanguard Machinery in the Philippines as an example

Production line configuration: Vibrating feeder + Jaw crusher + Cone crusher + Vibrating screen

Raw material: Basalt

Capacity: 100T/H

Project overview: The basalt is uniformly sent to the jaw crusher by a vibrating feeder for primary crushing. The cast steel frame and movable jaw can easily crush the high-hardness basalt. The coarsely crushed basalt is transported by a belt conveyor to the cone crusher for further processing. The unique structure and working principle can effectively and finely crush the basalt, and at the same time, there are fewer downtimes for maintenance than the counter crushing, which improves the stable production progress. After being finely crushed, the basalt aggregate is sent to a vibrating screen, the finished aggregates of different specifications and returned materials are screened out, and the unqualified basalt is returned to the cone crusherfor further processing.

A reasonable configuration of a basalt production line can not only effectively crush stone, increase the capacity and quality of aggregate, but also reduce unnecessary wear parts loss, help investors recover their investment as soon as possible, and make profits. As a manufacturer of various types of high-quality crushers, Vanguard Machinery Tech Co., Ltd has made extremely high achievements in production technology and standards, and can scientifically customize basalt crushing production line programs for investors to meet the needs of high-quality aggregates in different markets. What's more, our complete after-sales service system can solve your worries.

Email:vanguardtecads@gmail.com Tel:+86-371-5557 8880 Whatsapp: +86 133 3381 1995 WeChat: abmmining

2021-04-01

Multi-Cylinder Hydraulic Cone Crusher For Hard Stone-Vanguard Machinery Tech

2021-03-25

What Are The Advantages Of Making Sand From River Stone? How To Configure A Perfect River Stone Sand Production Line?

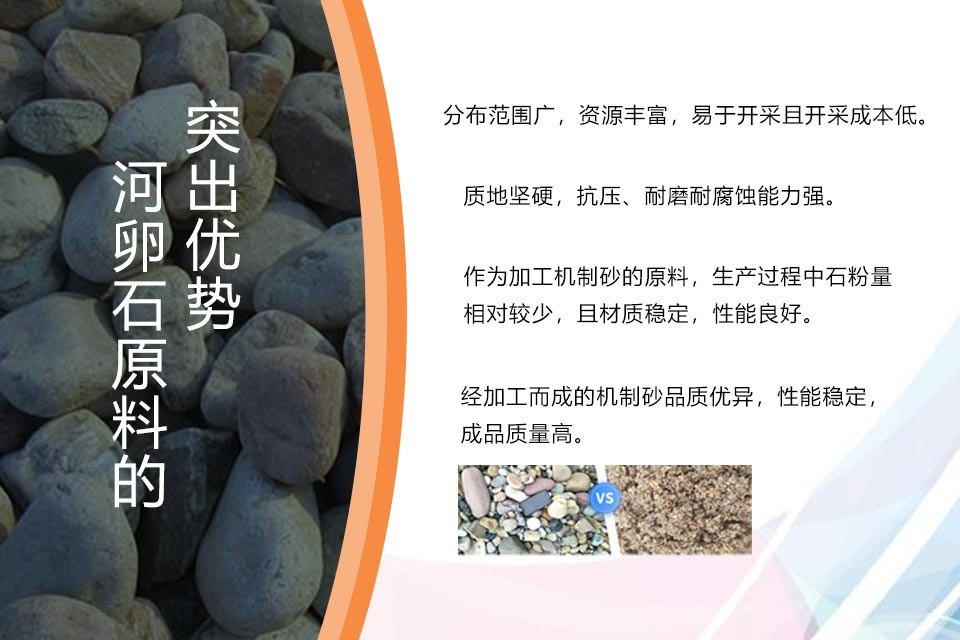

What Are River Stones

river stone is a hard, wear-resistant, stable chemical properties of silicate minerals, the river stone sand from natural river stones after crushing, sand making, screening, and a series of processing is an important industrial mineral raw materials, which is widely used in the field of engineering water conservancy and hydropower, high-grade road, highway, high-speed railway, passenger dedicated line, bridge, airport runway, municipal engineering, high-rise building sand production, and stone shaping. Pebble sand is also widely used as aggregate for concrete. In recent years, rivers stone as raw material processing of fine machine-made sand has also received high standards of manufacturers of affirmation and recognition!

In addition to Riverstone, granite, limestone, quartz sandstone, basalt, and even construction waste can be used to process machine-made sand. Why are pebbles still so attractive? What are its main advantages?

1. river stones are widely distributed, rich in resources, easy to mine, and low in mining costs, which can meet the needs of large-scale production.

2. river stones are hard rock, and their Platts hardness level is generally 2-3, the hardness coefficient is f=10-15, the texture is hard, compression, wear resistance, and corrosion resistance are strong.

3. With pebbles as raw materials for processing machine-made sand, the amount of stone powder in the production process is relatively small, and the material is stable, the performance is good, and the quality of the finished product is easy to control.

4. The machine-made sand made of river stones has excellent quality and stable performance. It is the preferred construction sand for high-rise buildings, highways, municipal engineering, water conservancy and hydropower, bridges, and other infrastructures.

The advantages of pebbles are the reasons for their popularity, but in order to process high-quality machine-made sand, it is particularly important to choose the right production equipment!

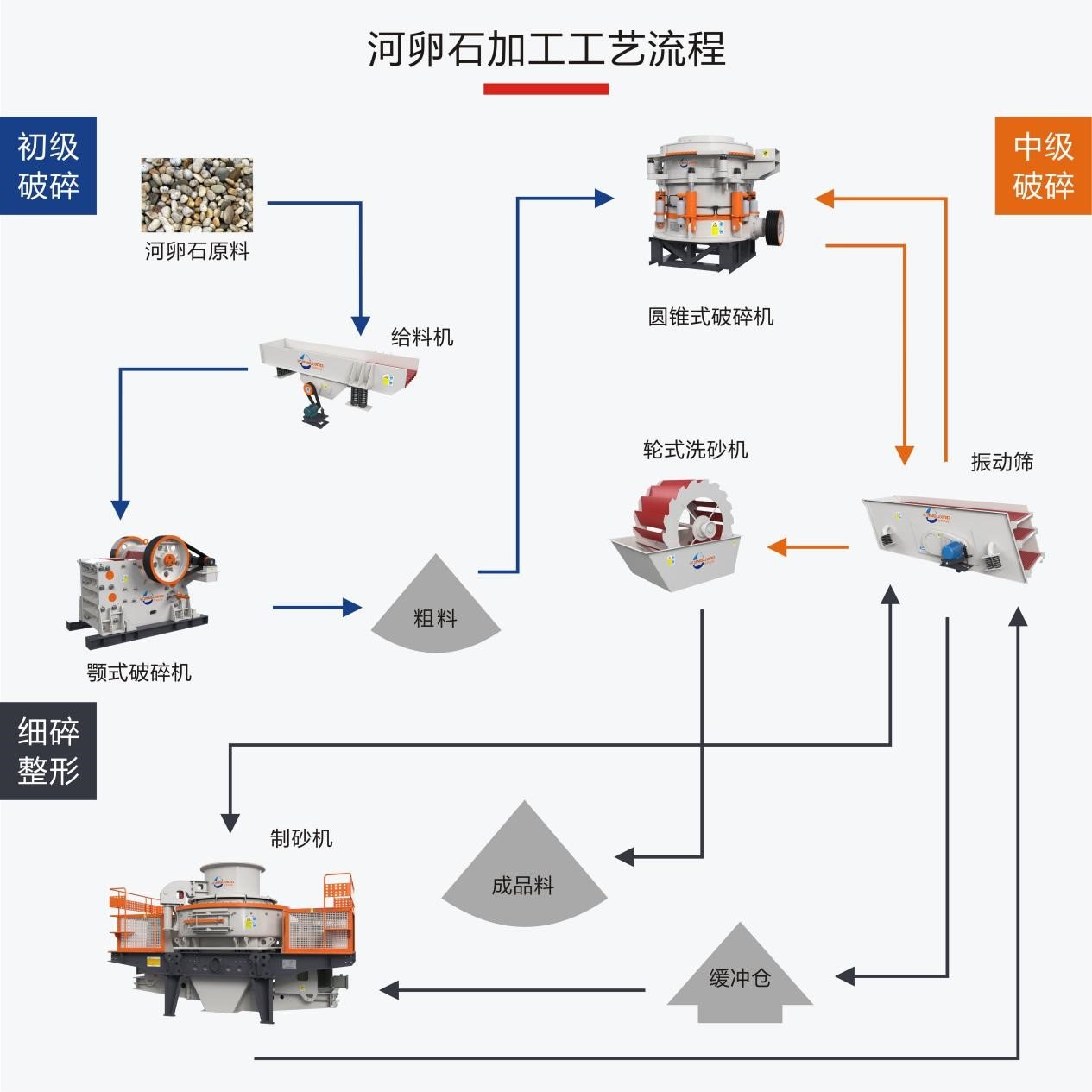

In general, sand making from river stone requires four steps: feeding, coarse crushing, fine crushing, and sand making. Because river stone is large in size, it needs to go through coarse crushing, medium and fine crushing, and sand making. In the link, there is a variety of equipment to choose from. The main equipment that needs to be used is a jaw crusher, impact crusher, and sand making machine. The auxiliary equipment includes a feeder, conveyor, and vibrating screen. If the local environmental protection is strict, dust and noise reduction devices are also required.

Main Equipment For Sand Making From River StoneCoarse Crushing Equipment

Jaw crusher. The feeding size is large, which can meet the crushing of 125-1500m materials, and the output size is 10-350mm. It is commonly used for coarse crushing of materials, and it can also be combined with two pieces of equipment for medium and fine crushing. The equipment structure is simple and the crushing efficiency is high.

Medium And Fine Crushing Equipment

The cone crusher can be used for medium and fine crushing of river stones with high material hardness. Most of the materials after crushing are cube-shaped, and the feeding size should be smaller than 560mm. The equipment has the advantages of simple structure, low cost, and large output.

Sand making equipment: 5X series sand making machine, VSI series sand making machine and mobile sand making machine are all common sand making machine equipment. They each have their own advantages. They can crush river stones into sand that meets the requirements, and the sand making effects are better.

Sand Washing Machine Equipment

The sand washing machine is mainly responsible for the end of the sand production line. It’s used to remove impurities such as mud on the surface of machine-made sand. Through the sand washing procedure, the quality of machine-made sand will be better and the corresponding market value will be higher.

A vibrating screen is a relatively common screening equipment, which can screen various stones and screen out finished products of different particle sizes. Generally, there are three-layer and four-layer screens, which are mainly used in the sand production line to form a cycle operation with the sand making machine.

Feeder And Conveyor

They are two auxiliary equipment in the production line, but they are also indispensable. The feeder is generally used before the jaw crusher, and the conveyor is the connecting tool between the main equipment of the entire production line.

The combination of that main equipment is a sand production line. Specific model adaptation needs to be configured according to various requirements such as production capacity, electricity consumption, and finished product granularity.

Process Flow Chart Of River Stone Sand Production Line

A reasonable combination of equipment and process can increase the overall benefits. Therefore, when developing the river stone sand making process for users, Vanguard mechanical engineers will first focus on understanding the customer's output, the requirements of the finished product, the surrounding environment, and whether it is a short-term trial operation or a long-term operation and so on. These are related to the investment cost and payback period.

2021-03-09

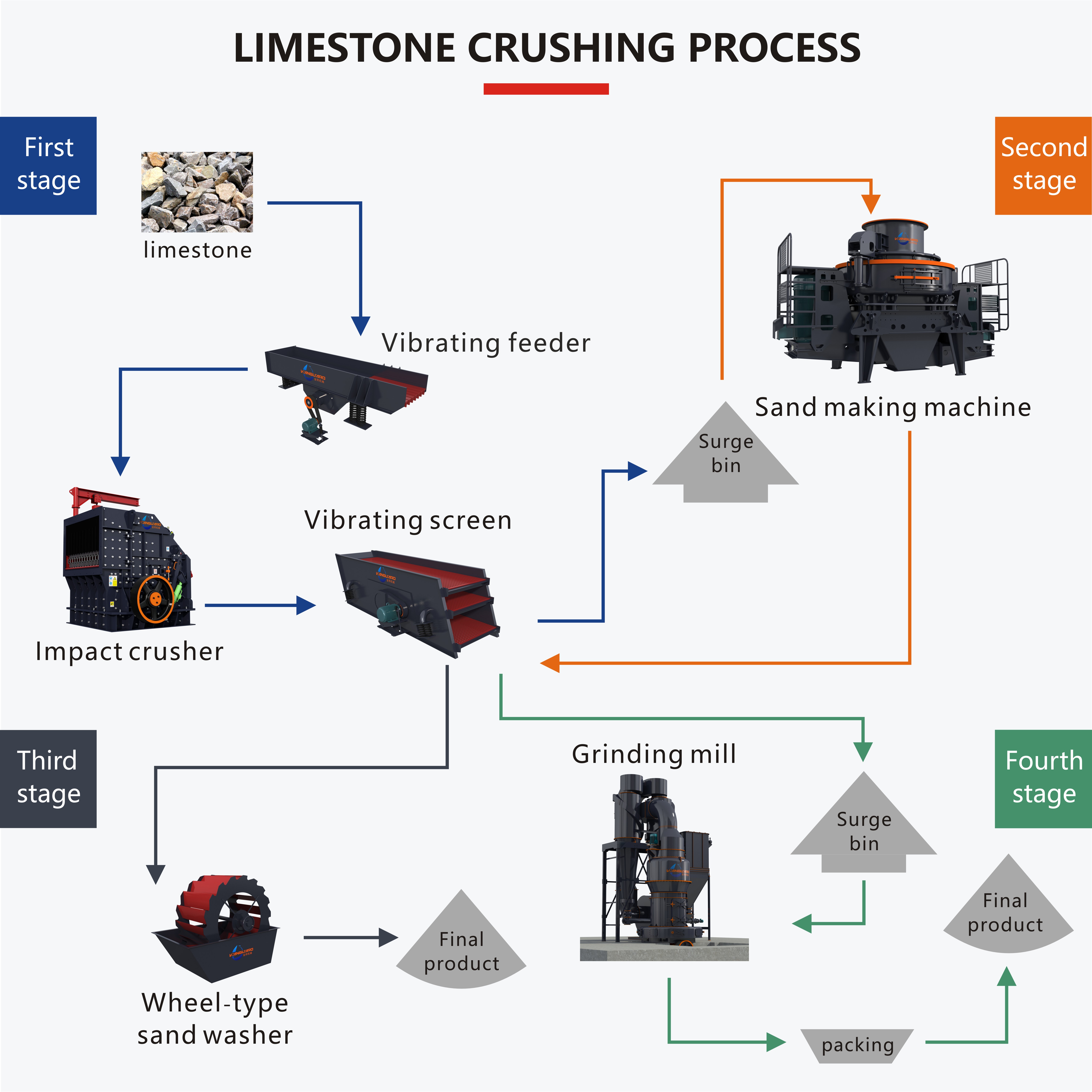

150tph Limestone Crushing Production Line Put Into Production in Hunan

Recently, Vanguard Machinery's after-sales installers have been working in the production site of a mining area in Hunan Province. The project is a 150tph limestone crushing production line, which has entered the stage of equipment installation and commissioning.

Warm Congratulations to Vanguard Machinery for Signing the EPC General Contracting Project of the 1,200 T/H Ore Production Line

Zhengzhou Vanguard Machinery Technology Co., Ltd. (hereinafter referred to as Vanguard Machinery) took the theme of "Innovative Manufac...

-

Crawler type mobile crushing plant is efficient crushing equipment, self-driven, technologically advanced, fully functional. The equipment c...

-

This Three Crawler Type Mobile Crushing Plant is a 100 T/H construction waste processing line. Vanguard Machinery crawler-type mobile crush...

-

In recent years, Zhengzhou Vanguard Machinery Tech Co., Ltd. has steadily increased the pace of overseas expansion. With the continuous im...